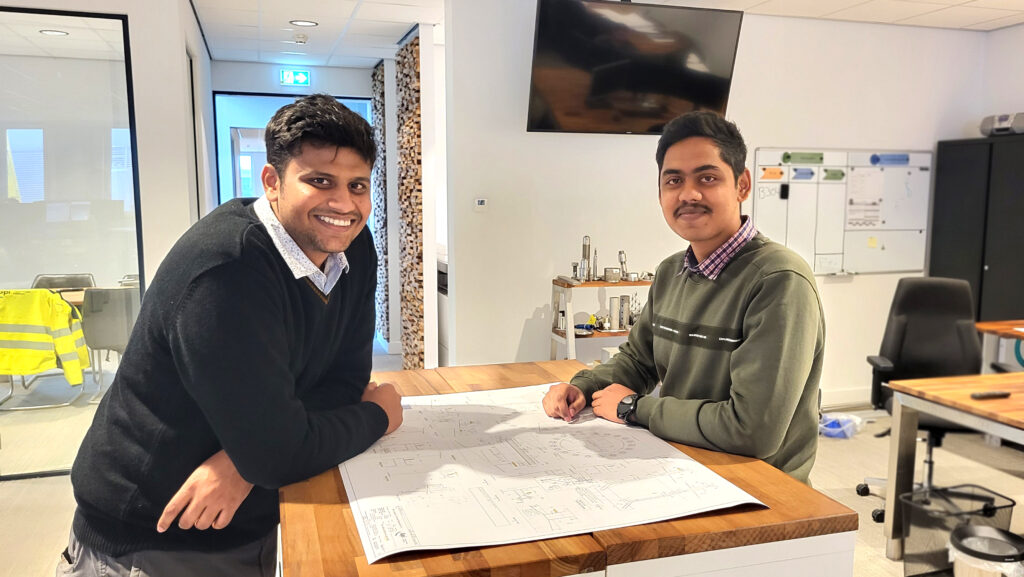

They truly realised how big some tanks are when they saw it with their own eyes in the production hall. In March last year, classmates Niranjan Bharadwaj (22) and Sanjeev Kumar (23) started working at Gpi India. Both were in the final stages of their mechanical engineering studies and completed an internship in the engineering department at Gpi’s Bengaluru office. They both stayed on after their internships and are now regular members of Gpi India’s engineering team.

Niranjan and Sanjeev not only followed the same study and internship, but were also in the Velocita Racing team for three years during their studies, where they built a complete single-seater race car themselves with their ‘Formula Student’ student team. Niranjan was team leader of this student team and explains, “We love engineering and enjoy experimenting and making things. Designing and building our own race car was very cool and educative.’

Getting started at Gpi

Their final internship of their mechanical engineering studies was at Gpi’s engineering department. Sanjeev says: ‘Someone from Gpi came to our school to look for students. We thought it was an interesting internship and soon we started working at Gpi. We learnt a lot about tank construction and to make 3d drawings of the tanks. It was a learning internship and we worked as part of a pleasant team. Both parties enjoyed this so much that we were allowed to continue working after our internship.’

Working at Gpi

Niranjan and Sanjeev now work full-time as engineers at Gpi in Bengaluru, making 3D designs of the tanks and supporting work preparation in Lopik.For Niranjan, the good collaboration with colleagues is a big plus: ‘Fortunately, Gpi is not a hierarchical company. Colleagues are very helpful and always do their best to help you. In addition, I have learned that tank construction is definitely not a niche, but a big field with a wide range of products with endless options. Every tank has its own custom-made specifications. This keeps engineering challenging.’

Visiting the Netherlands

To get to know the company and its processes better, they visited the Netherlands for a few months, where they could also see the tanks they draw in India in real life. Niranjan: ‘As an engineer, you see the figures and dimensions on the drawings, but you only realise the true size when you see the tanks in the production hall. I didn’t really realise that they are that big until we saw it here with our own eyes.’

Looking to the future

Sanjeev says about coming years: ‘It is my first real job, so I can learn a lot in this field, such as working more efficiently and gaining more knowledge of the relevant guidelines and standards. I look forward to see the company’s growth and progress in terms of implementing to newer production methods, material savings, supply chain improvements and its implementation.’ In the future Niranjan would like to have his own company in the metal and/or technical field. He explains: ‘I don’t really know what that will look like. For now, there is still plenty to learn and discover at Gpi!’